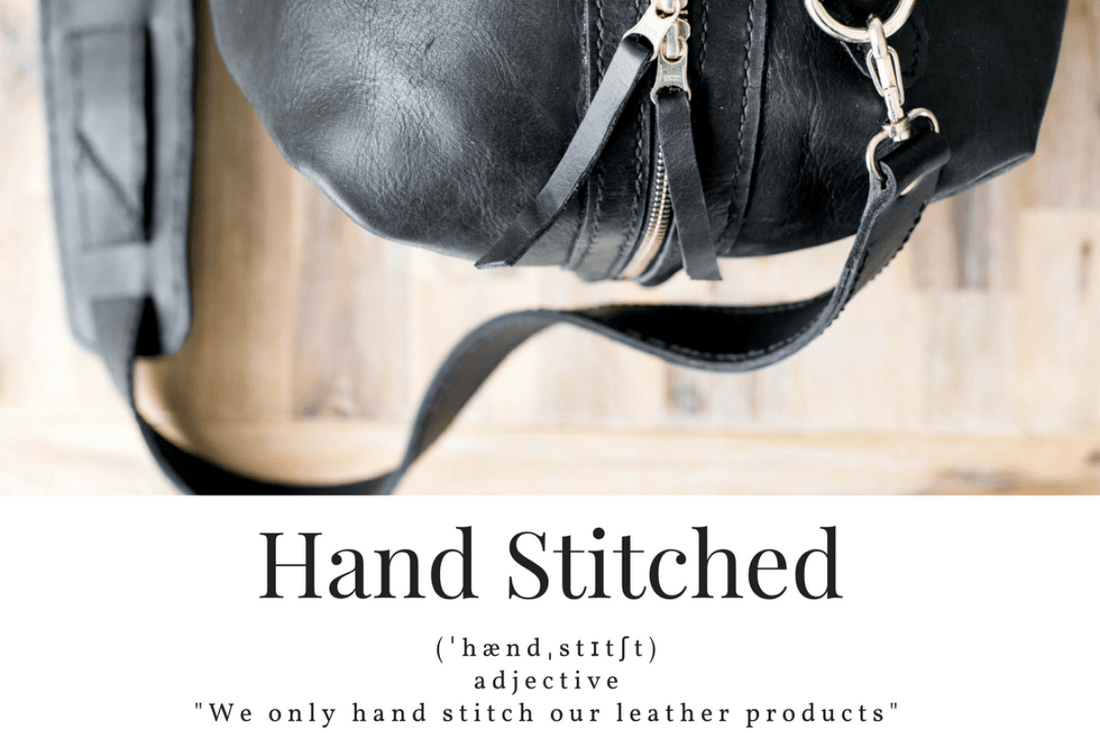

We Sew Our Leather by Hand

Share

“I have always believed that handmade products are more relatable and you can really feel that there was a person behind the item, this is why we hand stitch all our items at Swish & Swank,” shares Founder, Rouxnette

Since we started Swish & Swank a year ago, many of our customers have been surprised to learn that we don’t use a sewing machine to make our products. We love receiving this response, as it gives us the opportunity to describe this characteristic. At Swish & Swank, we stitch our pieces by hand for the aesthetics and durability that only hand stitching can achieve. As our founder Rouxnette puts it, “I wanted to make a collection that featured the craft at its finest form and interpretation possible, interpreted through contemporary designs.”

We have a team of leather crafters from Lesotho, who are highly skilled in this art form. The manual technique of hand sewing the leather offers a stronger suture than the traditional lock stitch created by sewing machines. Yes, the process is slower, but hand sewing is far superior to machine sewing. It is the best method of stitching two or more pieces of leather together for years of wear and service. Think about it, before machines, everything that required stitching was sewn by hand (the sewing machine did not exist until 1846).

The History

When you dig back into history books and artisan websites, you find that the hand stitch on leather was pioneered by saddle makers and tack makers for equestrians who needed to utilize a very tough stitch through a great thickness of leather. This is where the term “saddle stitch” derives from.

A traditional hand stitch, also known as a saddle stitch, is performed with two blunt needles, a sharp awl, typically waxed linen thread, and a good amount of patience. The process is simple to do but hard to master: Mark your holes, puncture the holes with an awl, and stitch together from both sides of the leather with each needle. The main benefit comes from the last step. By using two needles and coming at the leather from both sides you can create a locking stitch. When one part of the stitch breaks it does not affect the other segments of stitching and the piece will still be held together.

It’s a Long Process

Given that the process takes a long time, it takes one whole day to make a bag at Swish & Swank headquarters. This makes our process very time intensive and therefore more expensive to make. Though, for us, the stitching technique we use is a feature of our designs not just a necessary component of the construction process. In many ways, Swish & Swank’s designs are a function of an artisanal process that starts with the careful selection of materials and ends with the delicately executed saddle stitched construction of each piece we make.

“My decision to design my own collection and start a brand is largely due to the fact that I absolutely love the artistry and craft of traditional leather working. I have always wanted to make products that feature a human element and each piece would be treasured and appreciated by the buyer,” Rouxnette concludes.